Types of Gasification: Which is the best process?

There are several types of gasification available on the market today. But not all are created equal. The right process for a project depends on several variables including the type of waste being processed and the customers needs (heat and/or electricity). In this article, we will describe each type along with the common characteristics.

What is gasification?

Gasification is the process of converting organic materials (anything containing carbon) into a gas form known as Syngas or Producer Gas. Gasification has been around for hundreds of years. Initially developed to produce town gas for lighting and cooking in the 1800s, this was replaced by electricity and natural gas. Popularity of this process re-emerged during the World Wars when isolationism and fuel shortages became prevalent. Wood was the prevalent feedstock and by 1945, a large percentage of trucks, buses and other machines were fueled by gasification in Europe.

Types of Gasification

There are three broad gasification types: entrained flow, fluidized bed and moving bed, each having their own pros and cons.

Entrained Flow Gasification

In entrained-flow gasifiers, fine feedstock and air or oxygen (known as an oxidant) and/or steam are fed at the same time into the gasifier.

Entrained-flow gasifiers typically exhibit the following characteristics*:

- Fuel flexibility

- Large oxidant requirements – needs large amount of oxygen or air to operate

- Can either be oxygen or air blown, but most commercial plants are oxygen blown

- Uniform temperature within the reactor

- Slagging operation

- Short reactor residence time

- High carbon conversion, but low cold gas efficiency

- High level of sensible heat in product gas, heat recovery is required to improve efficiency

*Sourced from https://www.netl.doe.gov/

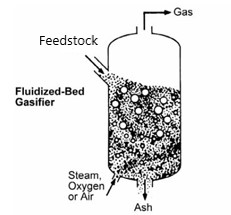

Fluidized Bed Gasification

Fluidized-bed gasifiers suspend the feedstock in an oxygen-rich gas. This creates a bed within the gasifier, which acts as a fluid. These gasifiers depend on the reaction between the feedstock and gas in order to efficiently mix feedstock particles with particles already undergoing gasification. To sustain the suspension that defines the process as fluidized, the feedstock particles within the gasifier must be small particles sizes (<6 mm).

Fluidized-bed gasifiers typically display these characteristics*:

- Load flexibility and high heat transfer rates

- Fuel flexibility, can gasify a wide range of feedstocks

- Moderate oxidant (air or oxygen) and steam requirements

- Uniform, moderately high temperature throughout the gasifier

- Higher cold gas efficiency than entrained-bed gasifiers, but lower carbon conversion

- Extensive char recycling is required

* Sourced from https://www.netl.doe.gov/

Moving Bed Gasification

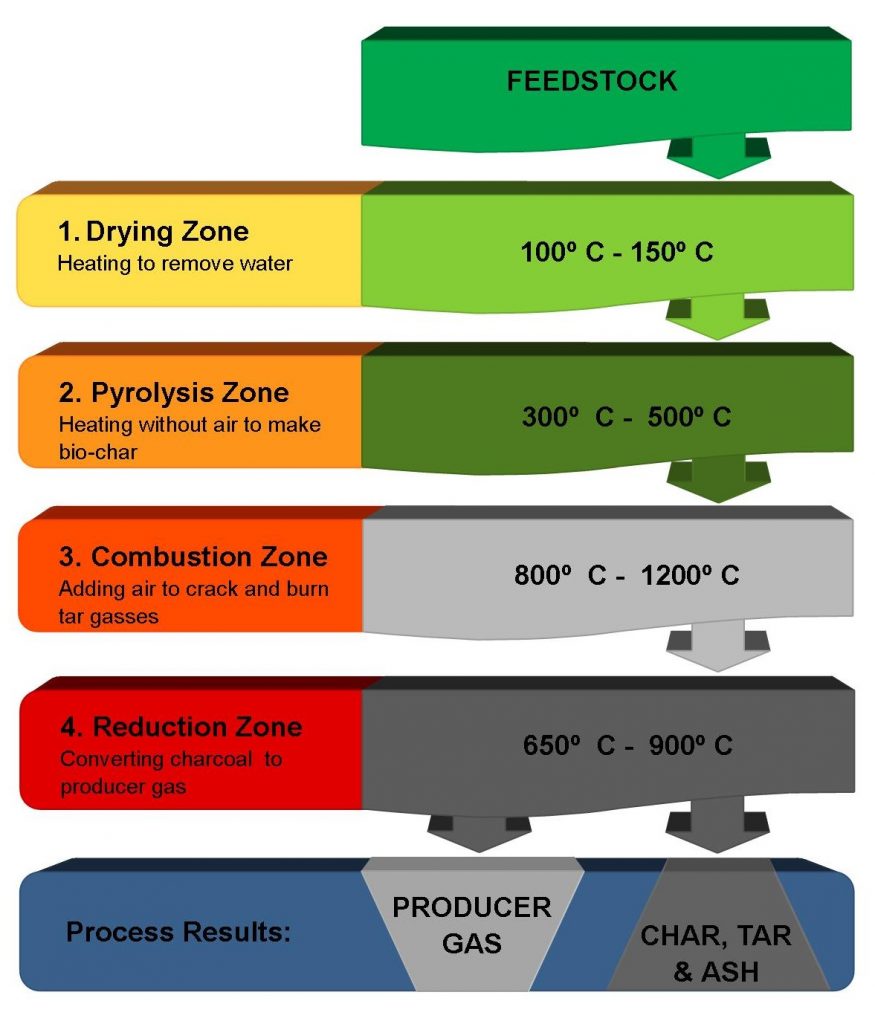

Moving-bed gasifiers are widely used for gasification of biomass due to their lower operating temperature, larger flexibility in feed size, and their ability to handle higher moisture content. There are three types of fixed bed gasifiers: updraft (counter-current), downdraft (co-current), and cross draft gasifier.

Moving-bed gasifiers share the following characteristics*:

- Simplicity of gasifier configuration and operation

- High equipment efficiency

- Relatively low oxidant (oxygen or air) requirement

- Less complex feedstock preparation with the use of coarse feedstock particles

- Produces gas at relatively low temperatures, thus no need for expensive high-temperature heat recovery equipment

- Feedstock flexibility

- High “cold-gas” thermal efficiency, when the heating value of the produced hydrocarbon liquids is accounted for

- High methane content in product gas

- Long feedstock residence time in gasifier and slag flow characteristics require carefully controlled feed size distribution for proper operation

- Hydrocarbon liquids such as tars and oils are produced; increased effort to clean produced gas if it is used for applications other than direct heating

- Explosion hazard without careful process monitoring

*Sourced from https://www.netl.doe.gov/

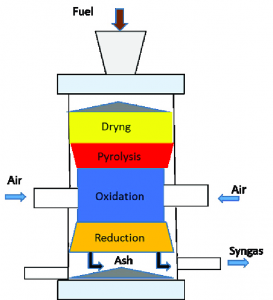

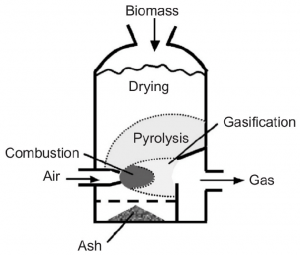

Updraft Gasifiers- These type of gasifiers are one of the simplest and most common types of gasifier for biomass. With updraft gasification, the fuel is supplied at the top and the air at the bottom so that fuel moves against the air flow.

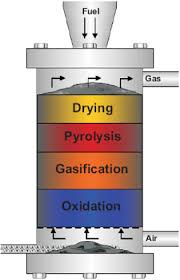

Downdraft Gasifiers– The downdraft design is essentially the same as the updraft design except that feed and air move concurrently from top to bottom of the gasifier. Advantage of the downdraft fixed-bed gasifier is that the tars are cracked down in the oxidation zone, thus the producer gas has lower tar content compared to other types of gasifiers.

Crossdraft Gasifiers- In this design, the biomass feed is introduced from the top and the air is from the side of the gasifier. The biomass moves down as it gets dried and finally, gasified while the air exits from the opposite side of the unit. The exit for the gas is more-or-less at the same level as that of entrance.

Summing it All Up

Which type gasification offers enough versatility, high quality producer gas and the best configuration?

In our opinion, the best option for most applications is Moving Bed gasification in the form of downdraft. Its ability produce clean gas due to tars cracking during the gasification process and the ability to offer a simple and modular design making maintenance and operation easier.